Deep Processing Service

At LZB, we specialize in providing a comprehensive range of aluminum deep-processing services. With expertise in drilling, Welding, milling, and bending, we offer customized solutions to meet your specific requirements.

Deep-Processing Service

At LZB, we specialize in providing a comprehensive range of aluminum deep-processing services. With expertise in drilling, Welding, milling, and bending, we offer customized solutions to meet your specific requirements.

Certifications

ISO 9001:2015 | SGS certificated | Critical to Quality Inspections

OUR SERVICES

At LZB, we specialize in providing a comprehensive range of aluminum deep-processing services. With expertise in drilling, Welding, milling, and bending, we offer customized solutions to meet your specific requirements.

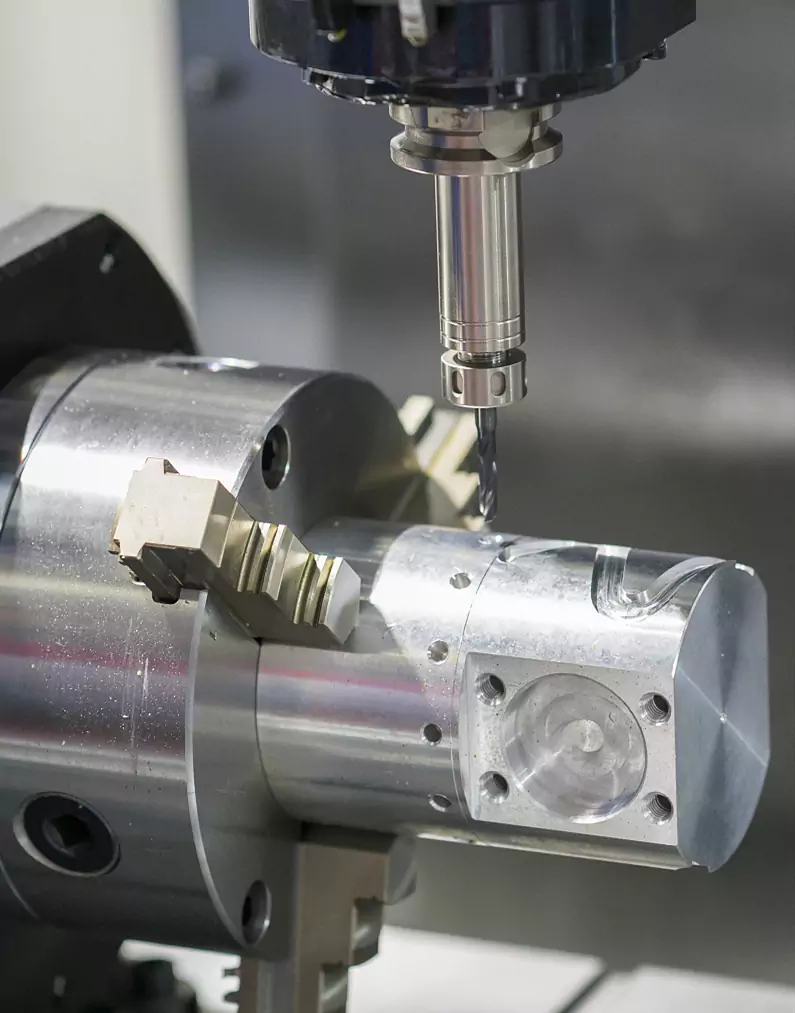

Drilling

Drilling

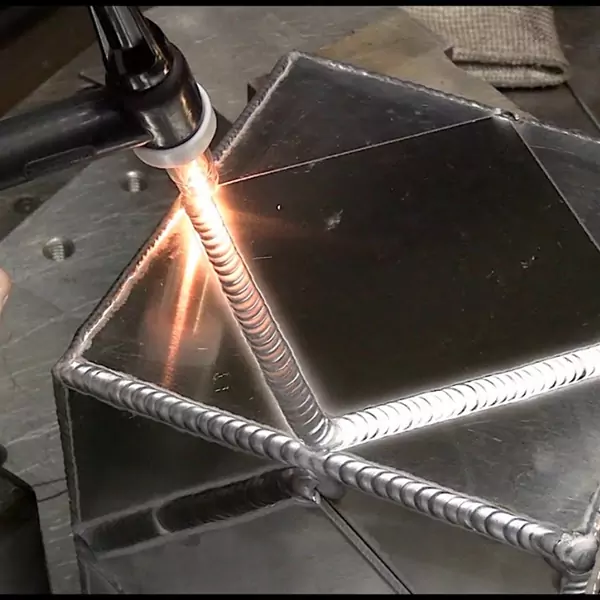

Welding

Welding

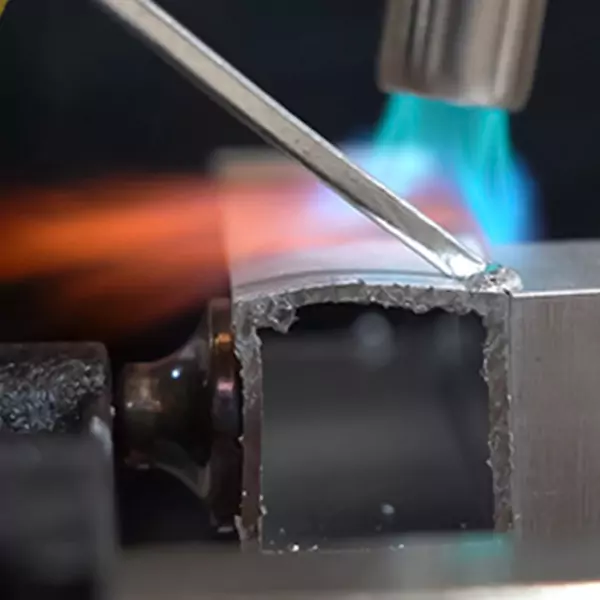

Milling

Milling

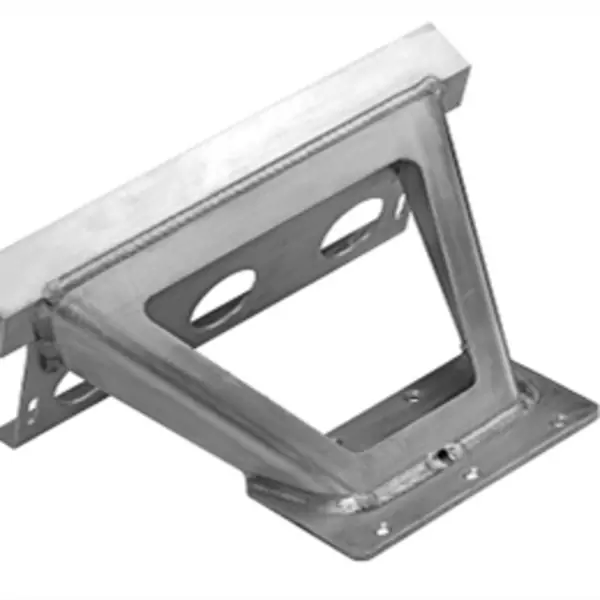

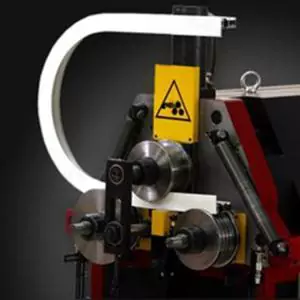

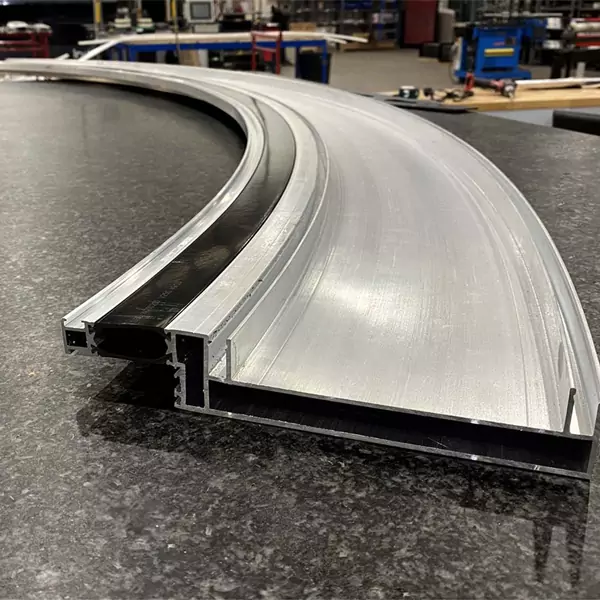

Bending

Bending

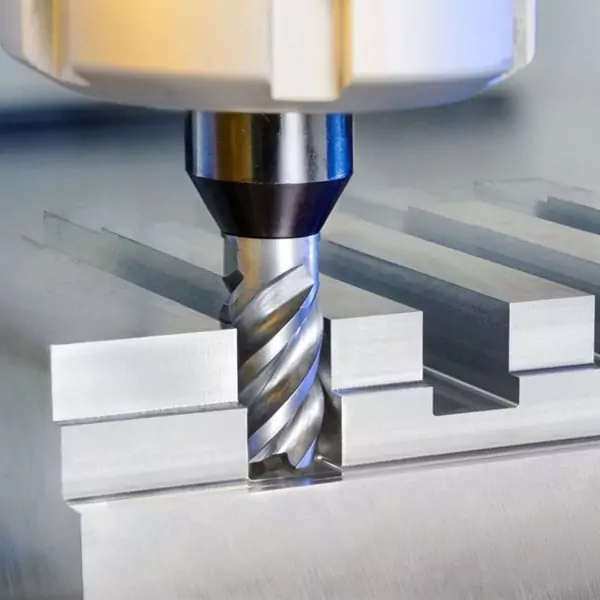

CNC Drilling

Drilling is a fundamental metalworking process that involves creating precise holes in aluminum materials. It utilizes a rotating drill bit, typically made of high-speed steel or carbide, to remove material and form the hole. Drilling is suitable for various applications, such as creating holes for fasteners, routing cables or pipes, and integrating components during assembly. It is widely used in industries such as construction, automotive, electronics, and manufacturing.

Welding

Welding is a technique that joins two or more aluminum pieces together by melting and fusing them. This process is used to create strong and durable connections between aluminum components. Welding finds extensive applications in manufacturing structures, automotive frames, piping systems, and many other industries where high-strength joints are necessary.

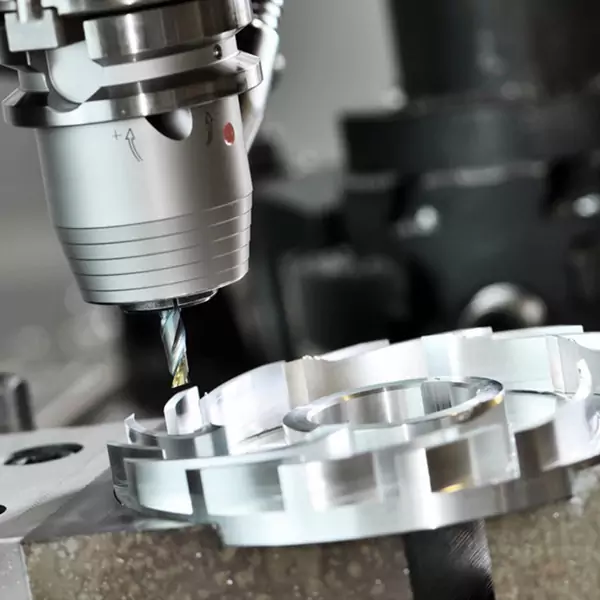

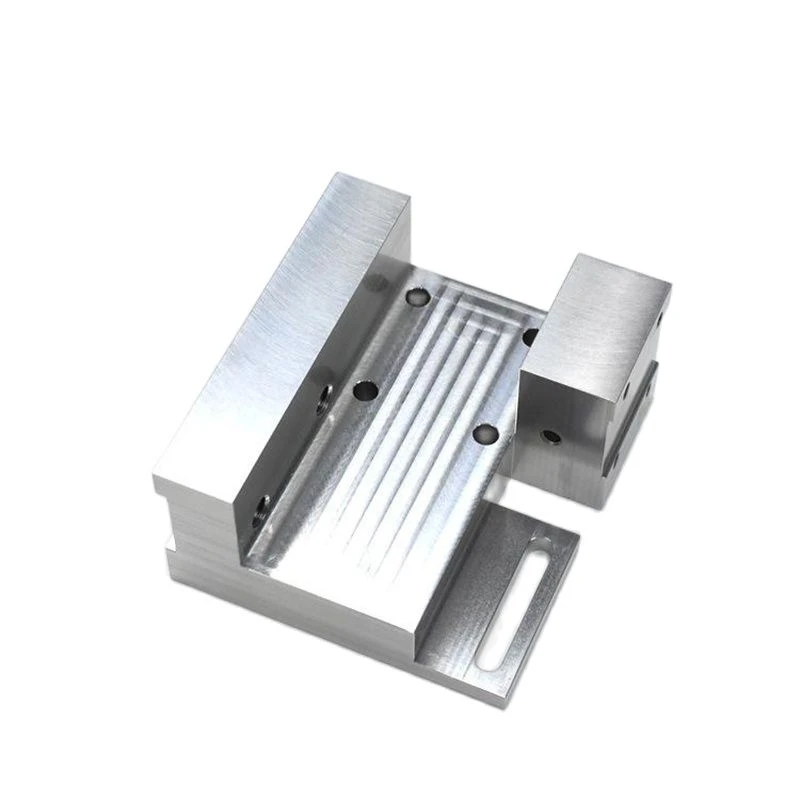

CNC Milling

Milling is a versatile machining process used to remove material from aluminum workpieces using rotary cutters. It involves the rotation of a cutting tool with multiple teeth, which progressively removes material as it moves along the workpiece. Milling can be performed on flat or curved surfaces and is capable of creating complex shapes, contours, and precision features. It is extensively utilized in industries such as aerospace, mold-making, precision engineering, and prototyping to produce components with high accuracy and surface finish.

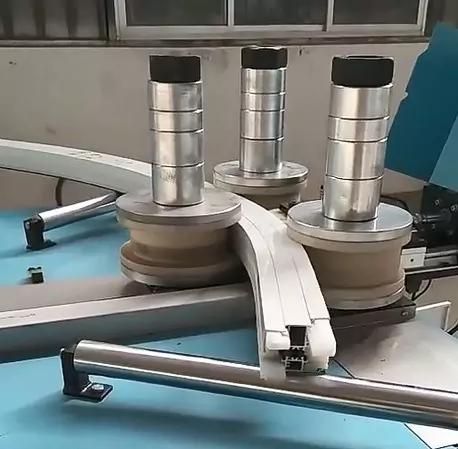

Bending

Bending is a forming process that deforms aluminum materials to create angles or curves. It involves applying force to the workpiece, typically using press brakes or specialized bending machines, to reshape it along a predetermined axis. Bending is employed to produce various aluminum components, including brackets, frames, enclosures, and curved panels. It is widely used in industries such as construction, automotive, aerospace, and manufacturing, where precise shaping and structural integrity are essential.

[Processing equipment] CNC five-axis machining center, CNC small and medium-sized computer molds (horizontal machining center, vertical machining center), CNC turning and milling compound machining center, CNC numerical control lathe, radial drilling machine (3050, 3040), precision forging Edge machine, automatic lathe centering machine, automatic lathe cutting machine, instrument lathe, wire cutter (fast wire, medium wire, slow wire), punching machine, ordinary turning and grinding drilling machine, grinding machine, tapping machine and electric welding machine and other supporting facilities Processing Equipment.

[Processing] CNC machining centers, CNC computer mold parts processing, laser cutting, automatic lathes, metal stamping, bell metal, non-standard parts processing, anodizing, etc.

[Testing equipment] three-dimensional, roundness detector, coarse particle size detector, image detector, salt spray detector, constant temperature and humidity detector, calipers, high-temperature plan, pass/stop gauge, plug gauge, universal angle ruler, Inside/outside micrometers, microscopes, etc.

[Machining accuracy] The length dimension tolerance is less than 0.05mm; the machining dimension tolerance of precision parts can reach ±0.01mm; the concentricity of one-time processing ⊙0.005mm; the parallelism of one-time processing precision ∥0.01mm; More guests higher level tolerance requirements.

[Common materials] Aluminum and aluminum alloys and common processing materials of their specifications.

Get Started With LZB Now!

We always want to make sure that our customers are getting the best deal, so let us know what you’re interested in and we’ll get back with a quote!